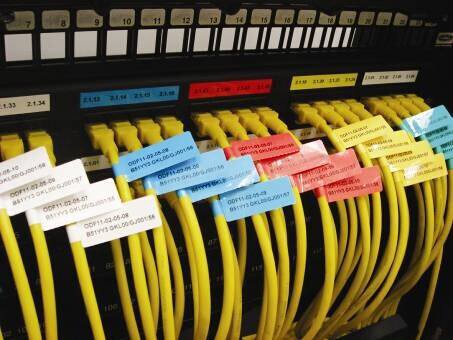

Wire harnesses need labels that can take heat, friction, and movement.

The wrong label peels or fades fast.

Use thermal transfer labels with strong adhesive and resin ribbon.

● Heat-resistant

● Flexible enough to wrap around wires

● Long-lasting and smudge-proof

Great for electronics, auto parts, and power tools.

With the transformation and development brought about by electrification, intelligence, and lightweight, the number of wire harnesses as the main network of circuits in the three major fields of automotive, industrial, and electronic is increasing, and the performance requirements are also getting higher. As the identity identifier of wire harnesses, wire harness labels are also given more special requirements.

1. For example, car wiring harness labels need to have characteristics such as heat resistance, oil resistance, and cold resistance; At the same time, he needs to be able to adapt to high mechanical strength and high-temperature environments for use. In addition, with the development of intelligence, cars are no longer just a row of sofas on top of an engine. Cars are not just means of transportation, but also a complex computer with the function of connecting everything for office and entertainment. Therefore, the electrical performance requirements of car wiring harnesses for wires, labels, clips and other auxiliary materials are also increasing. With the popularization of new energy vehicles, automotive wiring harnesses have been pushed into an era of rapid and high-quality development. At the same time, in order to avoid safety hazards caused by short circuits in wiring harnesses, more brand terminals have put forward higher requirements for fire prevention and flame retardancy.

2. Main features:

Try it risk free – We don’t charge cancellation fees